Circular Packaging: Transitioning from Single Use Materials

Circular Packaging: Transitioning from Single Use Materials

Arpita Kalanuria

Senior Research Fellow, IISD

Women Entrepreneurship Award Winner in Circular Packaging

Advisor, IISD Startup and MSMEs Center and

IISD Sustainable Fashion Prefessional Network (ISFPN)

Here the author talks about how reusable packaging can set a new standard, but the success of this new model will depend on all stakeholders involved. Are we ready for a packaging overhaul?

Many environmentalists will point out the Industrial Revolution in the 18th century, as an event that changed the consumption habits of mankind. As we started manufacturing products on a large scale, and moved from agricultural dominance to an urban way of life, consumer demand grew multifold and living standards in the western world improved greatly. The downside of this important revolution was the impact on the environment and the dependency and eventual strain on natural resources. With mass production & consumption, came waste, and the discovery and widespread use of plastics in the early 1900s only added to the waste woes.

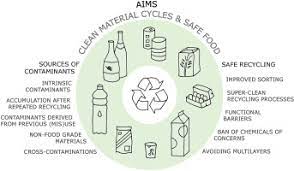

Of course, a lot has improved since then, we are now in the digital age with data being touted as the new oil. Waste management is more organized, recycling rates are higher, but the sheer quantity of waste produced will require more than recycling, and the most promising solution is Circularity. Circular economy is a term that has been gaining momentum in the past few years, and rightly so. Circularity in materials has the potential to displace waste, by keeping materials in use for several cycles, followed by repairing and then finally recycling. Increasing the longevity of materials will naturally have a positive impact on the environment, and the good news is that several countries are adopting Circularity with priority.

So what exactly happens when packaging goes circular? For one, circular packaging requires materials to stay in the loop, which would mean that the packaging materials would need revisiting. Next, to ease reuse on a large scale, end consumer participation is indispensable. India being the largest technology market, with a large part of the population awaiting immediate digitalization, is the right place to make changes at scale. India can set an example in the world, by adopting returnable & reusable packaging for FMCG products. Industrial packaging is an easier problem to solve, since bulk containers are already being returned, whether they are made from hard plastics, metals, or even corrugated boxes.

To improve a product’s lifespan, the use of durable materials like metals is imperative. Take for instance a bottle of shampoo revisited for circularity, if a consumer is able to return the empty containers for reuse, a lightweight durable and sterilizable metal like aluminium would be apt. An empty shampoo bottle is currently perceived as waste, but when you change that to an empty aluminium container, chances of the consumer throwing it in a bin as waste are very low. If a return value is attached to this empty metal container, and technology is used effectively to facilitate return, circular packaging can be a reality soon enough.

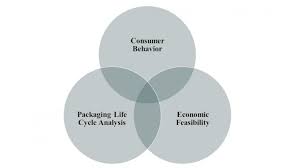

Stakeholder collaboration is the key in any system restructuring. In the case of circular packaging, brands, consumers, supply chain systems, block-chain technology, etc., need to work in tandem to create a reliable reuse system, for large scale applications. Supply chain management is a big factor in assuring success of a circular economy. By optimizing reverse logistics and strategic positioning of sterilization units, containers can be reused multiple times without a big increase in carbon emissions resulting from transport.

Extended Producer Responsibility (EPR) laws in India have been revised, and in the latest draft, the special committee that was constituted to evaluate mechanism for the implementation of the provisions of Plastic Waste Management Rules, 2016, has suggested that if the waste segregation is not done at source, it would be difficult to expect producers to implement EPR. Circular packaging can prove to be the missing link in effective waste management, by mitigating waste at source. Reusable packaging adoption can help brands achieve full compliance of EPR laws, and help reduce the burden on waste collection bodies.

Below is a circular packaging container, part of Amplepac's offerings for sanitizers:

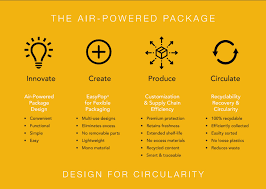

There awaits a USD 10+ billion innovation opportunity that can deliver significant user and business benefits in

the reusable packaging sector, according Ellen Mcarthur Foundation. The possibilities are endless, and it all starts with design.

Intelligent design, keeping all stakeholders in mind, coupled with consumer engagement and encouragement, can create the next reuse

ecosystem. For a long time, recycling was being pushed as the most effective solution to the current waste problem, but it seems now

that reuse could not only solve waste management issues, but also promise a clean sustainable future to the next generation.

The Author is a Senior Research Fellow (Circular Packaging, Sustainable Fashion) at Indian Institute of Sustainable Development (IISD), New Delhi, and leads IISD's Center of Excellence in Circular Economy Sustainability, IISD Startup and MSMEs Center and IISD Sustainable Fashion Prefessional Network (ISFPN).

Sustainable Packaging Design

Circular Packaging Business Model

Design for Circularity

Demystifying the Circular Economy of the Packaging

Sustainable Milk, Beverage and Food Packaging